Ahaziri nkenke metal stamping akụkụ na ekwe akụkụ

Nkọwa

| Ụdị ngwaahịa | ahaziri ngwaahịa | |||||||||||

| Ọrụ nkwụsịtụ | Mmepe ebu na imewe-nyefe samples-ogbe mmepụta-nyocha-elu ọgwụgwọ-ngwugwu-nfe. | |||||||||||

| Usoro | stamping, ekwe, miri ịbịaru, mpempe akwụkwọ metal fabrication, ịgbado ọkụ, laser ọnwụ wdg. | |||||||||||

| Akụrụngwa | carbon ígwè, igwe anaghị agba nchara, aluminum, ọla kọpa, galvanized ígwè wdg | |||||||||||

| Akụkụ | dị ka ndị ahịa eserese ma ọ bụ sample. | |||||||||||

| Mechaa | Ịgbasa eserese, electroplating, na-ekpo ọkụ-mikpu galvanizing, ntụ ntụ mkpuchi, electrophoresis, anodizing, blackening, wdg. | |||||||||||

| Mpaghara Ngwa | Akụkụ ụgbọ ala, akụkụ igwe ọrụ ugbo, akụkụ igwe injinia, akụkụ injinia ihe owuwu, akụrụngwa ubi, akụrụngwa enyi na enyi gburugburu ebe obibi, akụkụ ụgbọ mmiri, akụkụ ụgbọ elu, ihe ọkpọkọ, akụrụngwa akụrụngwa, akụkụ ihe egwuregwu ụmụaka, akụkụ elektrọn, wdg. | |||||||||||

Akwụkwọ ikike dị mma

1. Ngwaahịa niile na-emepụta na nyocha nwere ndekọ dị mma na data nyocha.

2. Akụkụ niile a kwadebere na-enweta ule siri ike tupu ebuga ndị ahịa anyị.

3. Ọ bụrụ na nke ọ bụla n'ime akụkụ ndị a mebiri emebi n'okpuru ọnọdụ ọrụ nkịtị, anyị na-ekwe nkwa iji dochie ha n'otu n'otu n'efu.

Ọ bụ ya mere anyị ji kwenye na akụkụ ọ bụla anyị na-enye ga-arụ ọrụ ahụ wee nweta akwụkwọ ikike oge ndụ megide ntụpọ.

Njikwa ogo

Vickers ike ngwá ọrụ.

Ngwa eji atụ profaịlụ.

Ngwa Spectrograph.

Ngwa nhazi atọ.

Foto mbupu

Usoro mmepụta

01. Akpụkpọ anụ

02. Nhazi ebu

03. Nhazi ịcha waya

04. Akpụkpọ ọkụ ọgwụgwọ

05. Mkpọkọta ebu

06. Ndozi ebu

07. Mwepu

08. electroplating

09. Nnwale ngwaahịa

10. ngwugwu

Ụdị akụkụ na-ehulata

Ụdị mpempe akwụkwọ a na-ahụkarị na-ehulata akụkụ:

1. Igbe workpieces: Cabinets, chassis, ngwá igbe, eletriki igbe, na ndị ọzọ yiri workpieces bụ ndị kasị juru ebe ụdị na mpempe akwụkwọ metal nhazi. Enwere ike ịgbanye ihe ndị dị larịị n'ime igbe dị iche iche site na iji ígwè na-ehulata, mgbe ahụ, a ga-ekechi ya ma ọ bụ jikọta ya ọnụ ka ọ bụrụ otu igbe.

2. Bracket workpieces: Ndị a workpieces, nke na-agụnye ìhè etiti brackets na arọ ígwè brackets, na-a mejupụtara nke ígwè efere na a dịgasị iche iche nke ogologo na diameters. Enwere ike ịmepụta braket nwere nkọwa dị iche iche site na iji mpempe akwụkwọ na-ehulata site n'ịgbanwe akụkụ na-ehulata na ogologo.

3. Gburugburu workpieces: Ndị a workpieces bụ isi mejupụtara spherical na conical ọcha, n'etiti ndị ọzọ. Enwere ike ịgbanye ọkara okirikiri dị larịị, nke nwere ụdị ngalaba, na ihe ndị ọzọ n'ime akụkụ okirikiri site na iji teknụzụ ịgbado mpempe akwụkwọ. Site n'ịchịkwa nke ọma nkuku na-ehulata, enwere ike ịrụzu akụkụ okirikiri okirikiri dị elu.

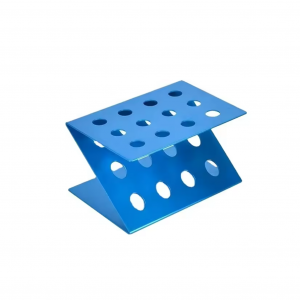

4.Bridge workpieces: Ndị a workpieces' ogologo na ekwe akụkụ dịgasị iche dabere na ụdị ojiji, dị ka ogbo ìhè guzo, ntụrụndụ ogige akụrụngwa, wdg Bridge-dị ka workpieces na a dịgasị iche iche nke nha nwere ike na-emepụta na mpempe akwụkwọ ekwe technology, na ha nwere uru nke kpọmkwem n'ọnọdu, elu nhazi nkenke, na mfe echichi.

5. Ndị ọzọ workpiece iche iche: E nwere a dịgasị iche iche nke workpiece ụdị, gụnyere ígwè owuwu, n'elu ụlọ, shells, na ndị ọzọ, na mgbakwunye na-ahụkarị mpempe akwụkwọ metal ekwe workpieces mbụ kwuru. Ọkachamara mpempe akwụkwọ metal ekwe longitudinal na transverse nhazi usoro dị mkpa maka dị iche iche workpiece ụdị.

Gịnị mere họrọ anyị

1.Expert mpempe akwụkwọ mpempe akwụkwọ na metal stamping akụkụ maka ihe karịrị afọ iri.

2. ọkwa dị elu nke mmepụta bụ ihe anyị na-elekwasị anya karịa.

3. Nkwado pụtara ìhè dị gburugburu elekere.

4. N'ime otu ọnwa, nnyefe na-eme ngwa ngwa.

5. Otu ndị ọrụ aka siri ike na-akwado ma na-akwado nyocha na mmepe.

6. Nye nkwado OEM.

Anyị na-enweta nkwupụta dị mma site n'aka ndị ahịa anyị yana mkpesa ole na ole.

8. Ngwaahịa ọ bụla nwere ihe eji arụ ọrụ dị mma yana ogologo ndụ dị mma.

9. Ọnụ ahịa asọmpi kwesịrị ekwesị.