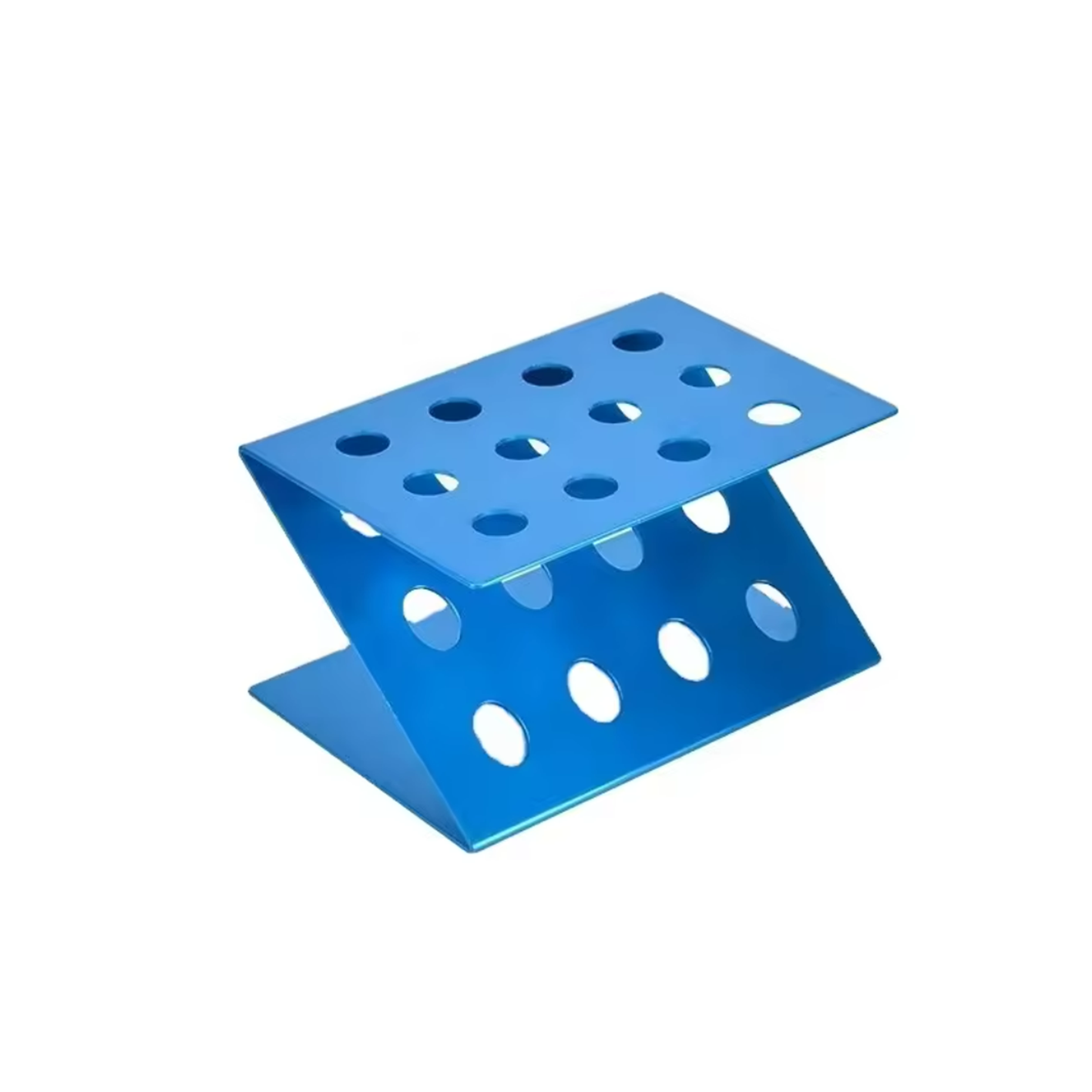

Igwe anaghị agba nchara Aluminom dị elu SPHC SPCC Mpempe akwụkwọ Metal Stamping Part

Nkọwa

| Ụdị ngwaahịa | ahaziri ngwaahịa | |||||||||||

| Ọrụ nkwụsịtụ | Mmepe ebu na imewe-nyefe samples-ogbe mmepụta-nyocha-elu ọgwụgwọ-ngwugwu-nfe. | |||||||||||

| Usoro | stamping, ekwe, miri ịbịaru, mpempe akwụkwọ metal fabrication, ịgbado ọkụ, laser ọnwụ wdg. | |||||||||||

| Akụrụngwa | carbon ígwè, igwe anaghị agba nchara, aluminum, ọla kọpa, galvanized ígwè wdg | |||||||||||

| Akụkụ | dị ka ndị ahịa eserese ma ọ bụ sample. | |||||||||||

| Mechaa | Ịgbasa eserese, electroplating, na-ekpo ọkụ-mikpu galvanizing, ntụ ntụ mkpuchi, electrophoresis, anodizing, blackening, wdg. | |||||||||||

| Mpaghara Ngwa | Akụkụ ụgbọ ala, akụkụ igwe ọrụ ugbo, akụkụ igwe injinia, akụkụ injinia ihe owuwu, akụrụngwa ubi, akụrụngwa enyi na enyi gburugburu ebe obibi, akụkụ ụgbọ mmiri, akụkụ ụgbọ elu, ihe ọkpọkọ, akụrụngwa akụrụngwa, akụkụ ihe egwuregwu ụmụaka, akụkụ elektrọn, wdg. | |||||||||||

Uru

1. Ihe karịrị afọ 10nke nka ahia ahia mba ofesi.

2. Nyeotu nkwụsị ọrụsite n'ichepụta ebu na nnyefe ngwaahịa.

3. Oge nnyefe ngwa ngwa, gbasara30-40 ụbọchị. Na ngwaahịa n'ime otu izu.

4. Njikwa mma siri ike na njikwa usoro (ISOemeputa na ụlọ ọrụ mmepụta ihe).

5. More ezi uche ahịa.

6. Ọkachamara, ụlọ ọrụ anyị nwerekarịa 10afọ nke akụkọ ihe mere eme na ubi nke metal stamping mpempe akwụkwọ metal.

Njikwa ogo

Vickers ike ngwá ọrụ.

Ngwa eji atụ profaịlụ.

Ngwa Spectrograph.

Ngwa nhazi atọ.

Foto mbupu

Usoro mmepụta

01. Akpụkpọ anụ

02. Nhazi ebu

03. Nhazi ịcha waya

04. Akpụkpọ ọkụ ọgwụgwọ

05. Mkpọkọta ebu

06. Ndozi ebu

07. Mwepu

08. electroplating

09. Nnwale ngwaahịa

10. ngwugwu

Usoro oxidation nke akụkụ stamping metal

A na-etinyekarị usoro ndị a na usoro oxidation:

1. Raw material nri: Jiri ọkpọkọ na-enye akụrụngwa na reactor iji na-ejigide kwesịrị ekwesị itule nke akụrụngwa n'ime.

2. Mmeghachi omume: Iji mee mmeghachi omume oxidation, tinye oxygen na reactor ma mezie usoro mmeghachi omume (dịka okpomọkụ, nrụgide, na oge mmeghachi omume).

3. Nkewa nke ngwaahịa: Jiri igwe nju oyi na-eme ka ngwaahịa ahụ meghachi omume jụrụ, gbanwee ya site na ikuku gas ka ọ bụrụ mmiri mmiri ma ọ bụ ụdị siri ike, wee jiri ihe nkewa kewapụ ngwaahịa ndị sitere na ihe dị iche iche.

4. Ịdị ọcha: Iji hụ na ngwaahịa mmeghachi omume ruru ịdị ọcha dị mkpa, mee ka ọ dị ọcha.

5. Nkwakọ ngwaahịa: Mgbe emechara ngwaahịa ndị ahụ, a na-achịkọta ha dịka ụkpụrụ nduzi na ụkpụrụ tupu erere ndị ahịa ma ọ bụ ziga ha na nhazi ọzọ.

N'ime ngwa ụfọdụ pụrụ iche, dị ka nrụpụta semiconductor wafer, usoro oxidation na-agụnye itinye ike okpomọkụ na oxidants (ụdị oxygen na mmiri) na mkpụrụ silicon iji mepụta mkpuchi silicon dioxide (SiO2). Ihe nkiri oxide a na-eje ozi dị ka oyi akwa na-egbochi etching iji kpuchido wafer site na etching na-amaghị nke ọma n'oge usoro etching, na-akwụsị mgbasa n'oge usoro ntinye ion, ma kwụsị nkwụsị nke ugbu a site na ịgafe na sekit.

OZI ANYỊ

1. Ndị otu R & D ọkachamara - Ndị injinia anyị na-enye atụmatụ pụrụ iche maka ngwaahịa gị iji kwado azụmahịa gị.

2. Quality Supervision Team - A na-anwale ngwaahịa niile tupu ezipu ya iji hụ na ngwaahịa niile na-agba nke ọma.

3. Ndị otu logistics dị mma - nkwakọ ngwaahịa ahaziri ahazi na nsochi oge na-ahụ maka nchekwa ruo mgbe ị nwetara ngwaahịa ahụ.

4. Independent mgbe-sales otu-enye n'oge ọkachamara ọrụ ndị ahịa 24 awa ụbọchị.

5. Ndị otu ndị na-ere ahịa ọkachamara - a ga-ekerịta ihe ọmụma ọkachamara kachasị mma iji nyere gị aka ịzụ ahịa nke ọma na ndị ahịa.