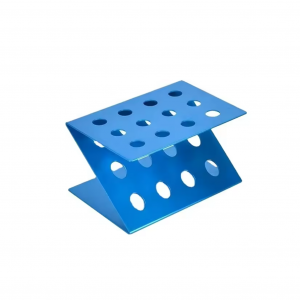

Akụkụ Omenala na-eme Bend Stamping Akụkụ galvanized mpempe akwụkwọ ọla

Nkọwa

| Ụdị ngwaahịa | ahaziri ngwaahịa | |||||||||||

| Ọrụ nkwụsịtụ | Mmepe ebu na imewe-nyefe samples-ogbe mmepụta-nyocha-elu ọgwụgwọ-ngwugwu-nfe. | |||||||||||

| Usoro | stamping, ekwe, miri ịbịaru, mpempe akwụkwọ metal fabrication, ịgbado ọkụ, laser ọnwụ wdg. | |||||||||||

| Akụrụngwa | carbon ígwè, igwe anaghị agba nchara, aluminum, ọla kọpa, galvanized ígwè wdg | |||||||||||

| Akụkụ | dị ka ndị ahịa eserese ma ọ bụ sample. | |||||||||||

| Mechaa | Ịgbasa eserese, electroplating, na-ekpo ọkụ-mikpu galvanizing, ntụ ntụ mkpuchi, electrophoresis, anodizing, blackening, wdg. | |||||||||||

| Mpaghara Ngwa | Akụkụ ụgbọ ala, akụkụ igwe ọrụ ugbo, akụkụ igwe injinia, akụkụ injinia ihe owuwu, akụrụngwa ubi, akụrụngwa enyi na enyi gburugburu ebe obibi, akụkụ ụgbọ mmiri, akụkụ ụgbọ elu, ihe ọkpọkọ, akụrụngwa akụrụngwa, akụkụ ihe egwuregwu ụmụaka, akụkụ elektrọn, wdg. | |||||||||||

Galvanizing usoro ụdị

1. Cyanide galvanizing: N'agbanyeghị na amachibidoro ya n'ihi nsogbu gburugburu ebe obibi, cyanide galvanizing nwere ọtụtụ ojiji.Ogo ngwaahịa ahụ dị mma mgbe ị na-eji obere cyanide (micro cyanide) plating solution, ọ dịkwa mma maka ịcha agba.

2. Zincate galvanizing: Usoro a sitere na cyanide galvanizing wee kewaa ya n'ime ụzọ abụọ: usoro "DE" nke Radio na Television Institute na Wuhan Material Protection Institute's"DPE".Ihe mkpuchi mkpuchi mkpuchi dabara adaba maka galvanizing agba, nwere ezigbo nguzogide corrosion, yana columnar.

3. Chloride galvanizing: ruo 40% nke mpaghara electroplating na-eji nke a ọtụtụ ebe.Ezigbo maka passivation na-acha ọcha ma ọ bụ na-acha anụnụ anụnụ, na nke kachasị mma maka ọgwụgwọ elu na-esote ngwa nke varnish na-agbaze mmiri.

4. Sulfate galvanizing bụ ọnụ ala na kwesịrị ekwesị maka na-aga n'ihu plating nke wires, ibe, na ndị ọzọ dị mfe, oké, na nnukwu ihe.

5. Hot-mikpu galvanizing: Iji hụ na zinc mmiri mmiri arapara n'ahụ plated akụkụ uniformly na densely, pickle akụkụ mbụ iji wepụ oxide oyi akwa.Mgbe ahụ, gbanye ha n'ime mmiri mmiri zinc n'ime tank nke na-ekpo ọkụ.

6. Electro-galvanizing: A na-ehicha elu elu nke ihe ndị a kpụrụ akpụ iji kpochapụ ihe ndị na-adịghị ọcha, pickled, na mmanụ na uzuzu na-ekpochapụ tupu ha etinye ya na ngwọta nnu zinc.A na-ekpuchi akụkụ ndị ahụ plated na oyi akwa zinc ekele maka mmeghachi omume electrolytic.

7. Mechanical galvanizing: A mkpuchi na-kere site mechanically colliding na chemically adsorbing zinc ntụ ntụ na plated components.

8. Molten galvanizing: A na-ekpuchi ígwè ahụ na oyi akwa nke zinc a wụrụ awụ site n'itinye ya na agbaze nke aluminum alloy, nke na-eme ka nkwụsị na-eyi na corrosion na-abawanye.

Usoro niile a kpọtụrụ aha nwere uru na ihe ndọghachi azụ nke onwe ha, na ha dabara adaba maka ụfọdụ ọnọdụ ngwa na ihe achọrọ.

Njikwa ogo

Vickers ike ngwá ọrụ.

Ngwa eji atụ profaịlụ.

Ngwa Spectrograph.

Ngwa nhazi atọ.

Foto mbupu

Usoro mmepụta

01. Akpụkpọ anụ

02. Nhazi ebu

03. Nhazi ịcha waya

04. Akpụkpọ ọkụ ọgwụgwọ

05. Mkpọkọta ebu

06. Ndozi ebu

07. Mwepu

08. electroplating

09. Nnwale ngwaahịa

10. ngwugwu

Usoro galvanizing na-ekpo ọkụ

Galvanizing bụ usoro ọgwụgwọ elu nke a na-eji egbochi corrosion ma gbakwunye mma mma site n'itinye akwa zinc n'elu igwe, alloys, na ihe ndị ọzọ.Ịmikpu mmiri na-ekpo ọkụ bụ usoro bụ isi.

A na-ezo aka na Zinc ka ọ bụrụ igwe amphoteric ebe ọ na-agbaze ngwa ngwa na ma acids na alkalis.Ikuku kpọrọ nkụ na-akpata obere mgbanwe na zinc.N'elu zinc, akwa akwa akwa nke zinc carbonate ga-etolite na ikuku iru mmiri.Zinc nwere obere nguzogide corrosion na sulfur dioxide, hydrogen sulfide, na ikuku mmiri.A na-emebi mkpuchi zinc ngwa ngwa, karịsịa na gburugburu ebe okpomọkụ dị elu, oke iru mmiri, na organic acids.

Zinc nwere ikike nke electrode nke -0.76 V. Zinc mkpuchi bụ mkpuchi anodic maka ihe nchara ígwè.Nzube ya bụ isi bụ ịkwụsị nchara nchara.Ejikọtara ikike ichekwa ya ozugbo na ọkpụrụkpụ mkpuchi.Enwere ike ime ka ihe ịchọ mma na ihe nchebe nke mkpuchi zinc dịkwuo mma site na ịgafe, ịnwụ, ma ọ bụ itinye mkpuchi mkpuchi gloss.

FAQ

Ajụjụ: Ị bụ ụlọ ọrụ azụmaahịa ma ọ bụ nrụpụta?

A: Anyị bụ ndị nrụpụta.

Ajụjụ: Kedu ka ị ga-esi nweta ntinye akwụkwọ?

A: Biko zitere anyị eserese gị (PDF, stp, igs, nzọụkwụ ...) site na email , ma gwa anyị ihe onwunwe, ọgwụgwọ elu na ọnụ ọgụgụ, mgbe ahụ, anyị ga-enye gị nkọwa.

Ajụjụ: Enwere m ike ịtụ naanị 1 ma ọ bụ 2 pcs maka ule?

A: Ee, n'ezie.

Q. Ị nwere ike na-emepụta dị ka samples?

A: Ee, anyị nwere ike na-emepụta gị samples.

Ajụjụ: Ogologo oge ole ka oge nnyefe gị dị?

A: 7 ~ 15 ụbọchị, dabere na iji quantities na ngwaahịa usoro.

Q. Ị na-anwale ngwongwo gị niile tupu ibuga?

A: Ee, anyị nwere 100% ule tupu nnyefe.

Ajụjụ: Kedu ka ị si eme azụmahịa anyị ogologo oge na mmekọrịta dị mma?

A:1.Anyị na-edebe ezigbo mma na ọnụahịa asọmpi iji hụ na ndị ahịa anyị na-erite uru;

2. Anyị na-asọpụrụ onye ọ bụla ahịa dị ka enyi anyị na anyị na-eji ezi obi na-azụ ahịa ma na-eme enyi, n'agbanyeghị ebe ha si.