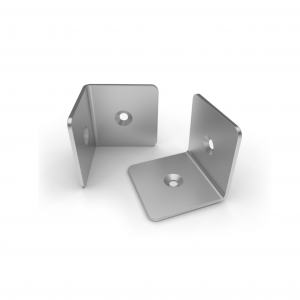

Akụkụ Omenala igwe anaghị agba nchara agbachi agbachi oji

Nkọwa

| Ụdị ngwaahịa | ahaziri ngwaahịa | |||||||||||

| Ọrụ nkwụsịtụ | Mmepe ebu na imewe-nyefe samples-ogbe mmepụta-nyocha-elu ọgwụgwọ-ngwugwu-nfefe. | |||||||||||

| Usoro | stamping, ekwe, miri ịbịaru, mpempe akwụkwọ metal fabrication, ịgbado ọkụ, laser ọnwụ wdg. | |||||||||||

| Akụrụngwa | carbon ígwè, igwe anaghị agba nchara, aluminum, ọla kọpa, galvanized ígwè wdg | |||||||||||

| Akụkụ | dị ka ndị ahịa eserese ma ọ bụ sample. | |||||||||||

| Mechaa | Ịgbasa eserese, electroplating, na-ekpo ọkụ-mikpu galvanizing, ntụ ntụ mkpuchi, electrophoresis, anodizing, blackening, wdg. | |||||||||||

| Mpaghara Ngwa | Akụkụ ụgbọ ala, akụkụ igwe ọrụ ugbo, akụkụ igwe injinia, akụkụ injinia ihe owuwu, akụrụngwa ubi, akụrụngwa enyi na enyi gburugburu ebe obibi, akụkụ ụgbọ mmiri, akụkụ ụgbọ elu, ihe ọkpọkọ, akụrụngwa akụrụngwa, akụkụ ihe egwuregwu ụmụaka, akụkụ elektrọn, wdg. | |||||||||||

Uru

1. Ihe karịrị afọ 10nke nka ahia ahia mba ofesi.

2. Nyeotu nkwụsị ọrụsite n'ichepụta ebu na nnyefe ngwaahịa.

3. Oge nnyefe ngwa ngwa, gbasara30-40 ụbọchị.Na ngwaahịa n'ime otu izu.

4. Njikwa mma siri ike na njikwa usoro (ISOemeputa na ụlọ ọrụ mmepụta ihe).

5. More ezi uche ahịa.

6. Ọkachamara, ụlọ ọrụ anyị nwerekarịa 10afọ nke akụkọ ihe mere eme na ubi nke metal stamping mpempe akwụkwọ metal.

Njikwa ogo

Vickers ike ngwá ọrụ.

Ngwa eji atụ profaịlụ.

Ngwa Spectrograph.

Ngwa nhazi atọ.

Foto mbupu

Usoro mmepụta

01. Akpụkpọ anụ

02. Nhazi ebu

03. Nhazi ịcha waya

04. Akpụkpọ ọkụ ọgwụgwọ

05. Mkpọkọta ebu

06. Ndozi ebu

07. Mwepu

08. electroplating

09. Nnwale ngwaahịa

10. ngwugwu

Usoro stampụ

Usoro nrụpụta nke a na-akpọ stampụ igwe na-akpụzi eriri igwe ma ọ bụ mpempe akwụkwọ dị larịị ka ọ bụrụ ụdị akapụtara.A na-etinye usoro nhazi dị iche iche na stampụ, gụnyere ịtinye stampị anwụ na-aga n'ihu, ịkụ ọkpọ, ịkwa akwa, na idebe oghere, ịkpọ aha ole na ole.Dabere na mgbagwoju anya nke ihe mejupụtara, akụkụ nwere ike itinye usoro ndị a niile n'otu oge ma ọ bụ na ngwakọta.A na-etinye eriri igwe ma ọ bụ mpempe akwụkwọ oghere n'ime igwe na-akụ stampụ n'oge a na-eme ya, nke na-etolite n'elu igwe na njirimara site na iji anwụ na ngwaọrụ.Stamping metal bụ ụzọ dị mma maka imepụta akụkụ dị mgbagwoju anya n'ọtụtụ buru ibu, gụnyere ngwa ngwa na oghere ụzọ maka ụgbọ ala yana obere sekit eletrik maka kọmputa na ekwentị.Ụgbọ ala, ụlọ ọrụ mmepụta ihe, ọkụ, ahụike na ụlọ ọrụ ndị ọzọ niile na-adabere na usoro stampụ.

Ụlọ ọrụ stamping metal

Maka ọtụtụ ngwa na ngalaba, anyị na-enye ọrụ stamping metal.Ngalaba ụgbọ ala, ikuku ikuku, na ahụike bụ naanị ole na ole n'ime ụlọ ọrụ anyị na-eji stampụ igwe na-eje ozi.

Ụgbọ ala Metal Stamping: Site na chassis ruo oghere ọnụ ụzọ ruo eriri eriri oche, a na-eji stampụ ígwè eme ọtụtụ narị akụkụ ụgbọ ala dị iche iche.

Aerospace metal stamping: N'ime usoro kachasị mkpa na mpaghara ikuku, a na-eji stampụ igwe mee ihe dị iche iche maka atụmatụ ikuku.

Enwere ike iji stampụ ígwè nkenke dị na ụlọ ọrụ ahụike iji mepụta akụkụ na ihe ndị na-egbo mkpa dị mkpa na ụkpụrụ nnabata.